Autoclaving. Containers are put in an autoclave and subjected to high-stress steam to kill microbes.

The sterilization techniques associated with aseptic processing usually change based on the personal aspect getting handled. One example is, glass containers are sometimes subject to dry heat, While liquid drug solutions are subjected to filtration, and rubber closures are sterilized by means of moist warmth.

They'll also have to have data that will help them prepare your venture. Working a pilot batch permits you to generate the creation program you should demonstrate co-packers that the merchandise is prepared for full-scale bottling.

Media fills could possibly be employed To guage aseptic techniques Utilized in the assembly of pre-sterilized factors and also to qualify operators for aseptic methods.

Parenteral nutrition merchandise: (if administered intravenously for provision of crucial nutrients to clients)

SOP connected to this method was transformed into 22 tiny and distinct actions. This shall make the identification of possibility associated with Each and every stage a lot easier and more exact. All hazards while in the inexperienced zone (RPN fewer than 34) are deemed acceptable, and no further more motion is important. All challenges in the pink zone (RPN is in excess of 104) are regarded not suitable, and the level of danger need to be decreased.

Enable’s make your concept a reality, alongside one another. We provide a full spectrum of expert services and sourcing capabilities to produce, deliver and supply your beverage eyesight from the first formulation to comprehensive vans of item.

Aseptic processing is sort of tough because it involves elaborate engineering of operations to prevent the contamination of products. Let’s discover these challenges even more.

Mycap® is developed Using the exact same, demonstrated closure process whatever the container or tubing resources. Validate Mycap® at the time, and use it freely across the entire generation approach.

Every pharmaceutical field is necessary to implement a successful risk administration plan within its good quality check here management technique. If the program is ineffective, risk Assessment and prioritization could possibly be incorrect. If this occurred, It might be a squander of time, effort, and dollars.

Considered one of the first great things about applying liquid bottle filling devices will be the implementation of meticulous high-quality control through the entire manufacturing method. These machines integrate automatic devices that observe Each individual phase, drastically reducing the likely for problems and defects.

Unqualified workers managing the process. Lack of checking and supervision. No checklist to doc the absence of any vacant bottles inside of glass bottles washing equipment. No counter-check.

Linked SOP must be revised to include using a Filling in Sterile Manufacturing checklist to assure the absence of any empty glass bottles inside of bottle washing machine all through breaks and at the end of change. The checklist ought to be counter-signed by device supervisor.

Preserving an aseptic atmosphere requires in excess of the mandated testing. Providers must invest significantly in deliberately-designed controls that validate and qualify the aseptic course of action.

Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Hailie Jade Scott Mathers Then & Now!

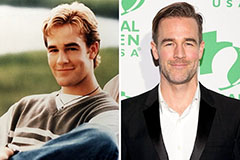

Hailie Jade Scott Mathers Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now!